Case studies & Application Notes

- Home

- Case study

- Case Study: Design and start-up of a continuous purification process

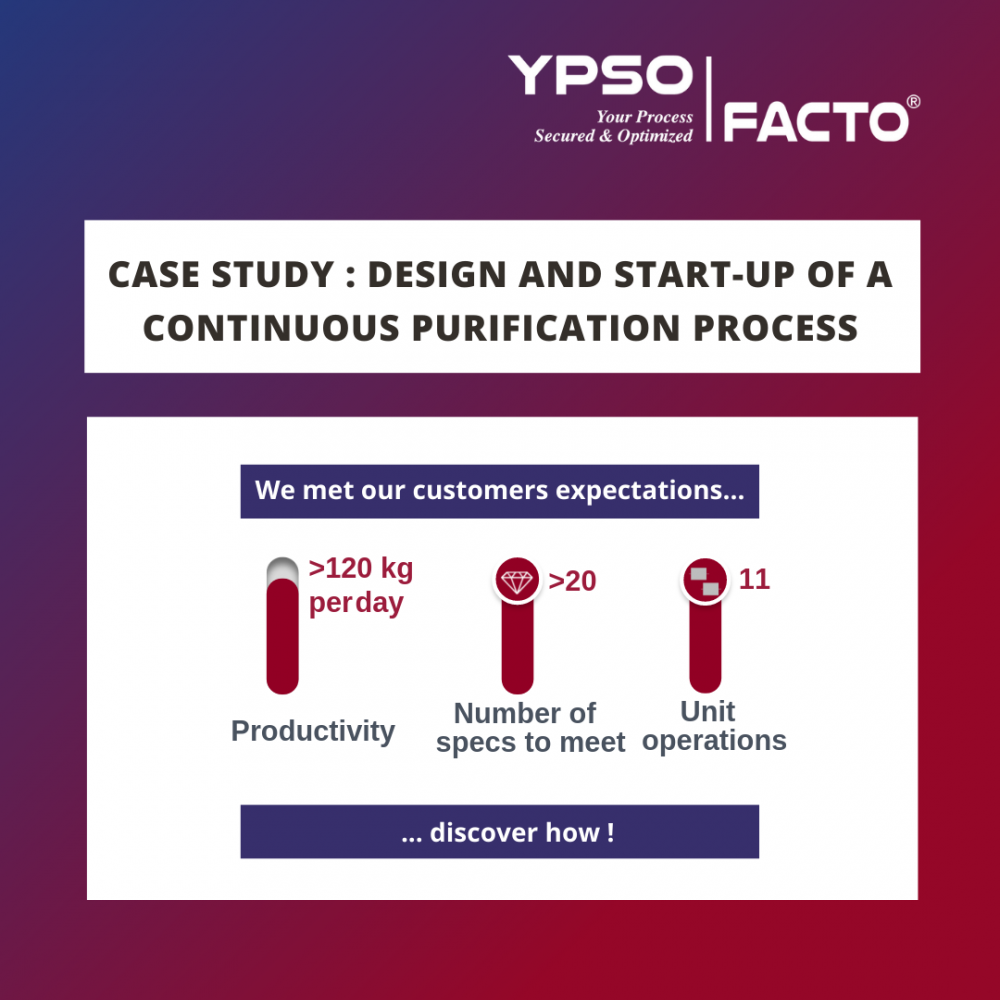

Case Study: Design and start-up of a continuous purification process

- by Ypso-Facto

- July 08, 2021

Challenge

-

Existing pilot batch process for the purification of omega-3 fatty acids from natural oil (11 unit operations)

-

Shift to an industrial continuous production

Methods

-

Analysis of the existing batch system and elaboration of mass balances

-

Definition of technological choices

-

Selection of an equipment supplier to build the unit

Achievements

-

Successful transfer from a pilot batch process to a continuous commercial process (GMP manufacturing in an ATEX environment)

-

Assistance for the industrial unit start-up and the manufacturing of 3 validation batches

Contact us to discuss your own challenges!

Ypso-Facto has been helping Pharmaceutical and Biopharmaceutical companies optimize their processes since 2014. We offer technology enabled services and proprietary software to solve some of our industries biggest challenges : make (bio)pharmaceutical processes safer, more cost efficient, and environmentally friendly.

We have a unique approach based on technologies which can combine multiple dimensions:

- The educated guess or expertise of the experts, which we call G

- The use and contextualization of experimental data, which we call X

- And the predictive simulation based on mechanistic modelling, which we call P.

Depending on your product and process, we have mechanistic models that we can use, or we can work with your experimental data to build one. Altogether, that is our unique GPX approach.

#chromatography #mechanistic #modeling #simulation #purification #omega3 #naturaloil #continuous #processdevelopment #batch

Recent news

BLog

- Interview : « L'expertise humaine est un précieux outil pour évaluer la fiabilité d'un modèle » (French)

- From exploration to expansion: refining process understanding through simulation

- Ever wanted to leverage mechanistic modeling but worried it’s too time-consuming?

The Explore Package makes it simple and efficient!

Ypso-Facto is a service company helping industrial firms to develop, optimize and secure their chemical processes and bioprocesses.

Contact Us

-

Address: 19 avenue Foch

54000 NANCY - FRANCE -

LU +352 20 21 39 14

FR +33(0) 355 961 650

- contact@ypso-facto.com